One of the most important things that sets Power Lift apart is our unlimited range of helical pile and anchor systems — which we manufacture ourselves!

One of the most important things that sets Power Lift apart is our unlimited range of helical pile and anchor systems — which we manufacture ourselves!

In our experience, we’ve learned that there’s one way to get the results you want — a custom-made helical design solution that’s based on a structure’s specific needs.

Earliest Use

Earliest UseA blind Irish engineer named Alexander Mitchell is credited as the first person to start using helical piles for their superior performance. Helical piles (sometimes called “screw piles”) began appearing in the 19th century as pile foundations for lighthouses. Mitchell found the helical design to be highly effective for constructing lighthouses and other structures on top of mud or shifting sands. He described their use in a paper in Civil Engineers and Architects Journal in 1848.

Over the next half-century, more than 100 screw pile lighthouses were built up and down the U.S.’s eastern coastline. And although they were made from cast or wrought iron, they had limited capabilities. Modern helical piles are made from a variety of materials and can provide impressive bearing and tension capacity for any kind of structure. For the past 20 years, Power Lift Foundation Systems has used custom-designed helical piles to provide foundation support for projects across the United States. Our specialty and what sets us apart from the rest is our custom design approach. When it comes to large capacity helical screw piles in the central United States, Power lift is unmatched.

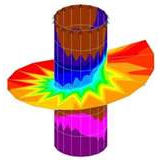

At Power Lift, our helical piles are custom-designed to offer the capacity required and can be extended to any required depth — efficiently and economically. Most companies purchase manufactured low capacity piles from a distributor and apply the same cookie cutter approach to all projects. For instance, if piles are used to support new pile caps with a service load of 400 kips, they might install eight 50-kip piles or four 100-kip piles. At Power Lift, we would likely choose one 400-kip pile. We manufacture our own pile shafts (both round and square) as well as the helix plates. Every facet of the helical pile is custom tailored to each project’s unique needs

At Power Lift, our helical piles are custom-designed to offer the capacity required and can be extended to any required depth — efficiently and economically. Most companies purchase manufactured low capacity piles from a distributor and apply the same cookie cutter approach to all projects. For instance, if piles are used to support new pile caps with a service load of 400 kips, they might install eight 50-kip piles or four 100-kip piles. At Power Lift, we would likely choose one 400-kip pile. We manufacture our own pile shafts (both round and square) as well as the helix plates. Every facet of the helical pile is custom tailored to each project’s unique needs

Although there are huge amounts of data available about predicting helical performance, we believe that custom designs should be field-tested for capacity verification. That’s why we routinely perform full-scale load tests per ASTMD-1143 and often discover that our piles are able to exceed our calculated predictions and handle greater loads than expected.

Although there are huge amounts of data available about predicting helical performance, we believe that custom designs should be field-tested for capacity verification. That’s why we routinely perform full-scale load tests per ASTMD-1143 and often discover that our piles are able to exceed our calculated predictions and handle greater loads than expected.

Special Note: All of our testing is observed by independent laboratories and the results are certified by our engineers.

Our most common uses for helical screw piles and anchors are new construction and foundation repair.

In addition to the above, there’s a wide variety of applications for our premier products:

In some cases, we can install as many as 100 piles in one workday with one crew. Just as there are many Applications for helical screw piles and anchors, there are plenty of advantages to using them:

And perhaps most importantly, Power Lift helical piles are custom-designed to solve the project’s specific needs.

There is no “one size fits all” solution. Our team analyzes the load requirements, soil, and site conditions and develops the most efficient and economical pile configuration for your needs.

Guide for PL Helical Screw Pile & Anchors